Click: 39

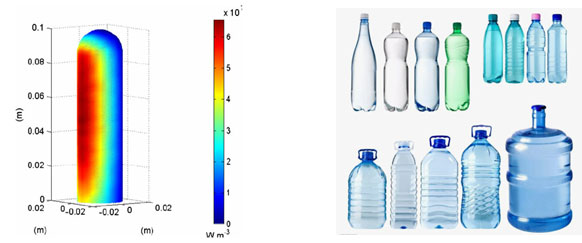

A preheating step is necessary to heat the preforms to the appropriate temperature distribution above the plastic transition, which is typically around 75°C~130 °C for PET. This stage is generally performed using infrared (IR) heaters, taking advantage of the semitransparent behaviour of PET submitted to IR radiation.

The short-wave IR radiation is easily absorbed by the PET preform. Some of the radiation passes through the preform and is reflected back onto the preform by a reflector located behind the preform. This way the heat loss is kept to a minimum.

Benefits of IR heating for PET preforms:

•High efficiency of rapid heating;

•Less energy and space required compared to other systems;

•Lower total cost of operation through the whole lifespan;

•Uniform temperature distribution between the inner and outer parts of preform wall.